|

Changzhou Chuangxin Drying Equipment CO.,LTD.

|

Gold Index: 6328

8 - 5kw Flash Dryers with 600 -1500m3/h for drying the heat sensitive materrials

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Quick Detail: &n

Quick Detail:

|

Place of Origin: |

Jiangsu China (Mainland) |

Brand Name: |

chuangxin |

Model Number: |

XSG |

|

Certification: |

CE |

Warranty: |

12 months |

After-sales Service Provided: |

Engineers available to service machinery overseas |

|

material: |

Stainless steel,carbon steel |

type: |

XSG-3 |

barrel diameter: |

200mm |

|

main machine dimensions: |

300x3.6 |

main machine power: |

5-9kw |

air velocity: |

300-800m3/h |

|

water evaporation capacity: |

10-20lg/h |

|

|

|

|

Description:

XSG Series Revolving Flash Vaporization Dryer is a new model of drying equipment.It is represents advanced

technology,compact structure and wide application.It has a large production capacity with high quality,less energy

consuming and non-pollution.Processes of drying,crushing and sieving complete in the same equipment once.Its

performance is up to the international advanced level.

Applications:

Inorganic:Boric acid,calcium,copper sulphate, iron oxide rust,carbonic acid barium,oxidizing the antimony three times,various kinds of metal caustics,various kind of heavy metal salt,formatting the ice crystal,etc.

Organic matter:Atrazine(pesticide),cadmium laurate,benzoate acid,germicide,sodium oxalate,cellulose acetate and so on.

Pottery:kaolin,silicon dioxide,clay.

Specifications:

- Revolving flash dryer

2. Model:XSG

3. Usage:drying material in pieces,tapes and particles shape

Competitive Advantage:

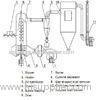

1. Options of feeders make sure continuous and stable feeding,so phenomenon of bridging won’t come up.

2. Set up the special cooling device in the desiccator bottom has prevented the suppliers from producing the rotten phenomenon in the high temperature district of the bottom.

3. Special atmospheric pressure seal installation and bearing cool the device,the service life of the running part of effective extension.

4. Special points of wind device have reduced the obstruction of the equipment,and have offered the wind amount of treatment of the desiccator effectively.

5. Dry room equips with hierarchical ring and swirl slice,suppliers detailed degree and end moisture content adjustable.(Such as calcium carbonate end but from regulator to moisture content.1%)

6. As to other dry methods,can increase the proportion of the suppliers effectively.

7. Circumference speed is high in the drying chamber,the time of material staying is short in order to prevent sticking on the inner wall and to prevent material deterioration.It is high efficient,fast,small space occupancy and great production capacity.

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Changzhou Chuangxin Drying Equipment CO.,LTD. [China (Mainland)]

Business Type:Manufacturer

City: Changzhou

Province/State: Jiangsu

Country/Region: China (Mainland)